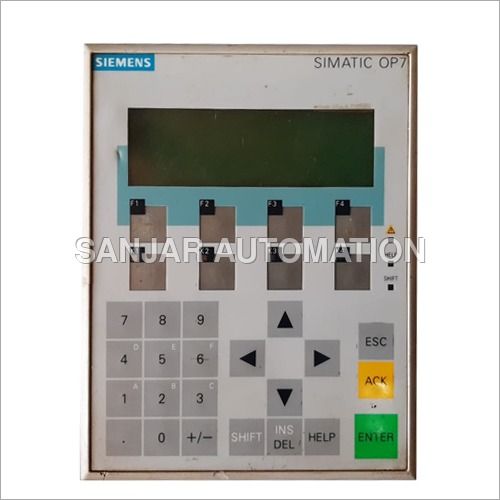

SIMATIC OP7 HMI Display

Price 13500 INR/ Piece

SIMATIC OP7 HMI Display Specification

- Frequency

- 50/60 Hz

- Mounting Type

- Panel Mount

- Weight

- Approx. 0.7 kg

- Phase

- Single Phase

- Features

- User-programmable, Message and Alarm Display, Password Protection

- Control Type

- Touch / Membrane Keypad

- Cable Length

- Depends on installation, typically up to 15 meters

- Automation Grade

- Automatic

- Processor Type

- Integrated Microprocessor

- IP Rating

- IP65 (Front)

- Application

- Industrial Machine Control

- Connectivity Type

- RS-232, RS-485, MPI

- Screen Size

- 4.5 inch (Monochrome LCD)

- Material

- Plastic and Metal

- Power

- 24V DC

- Temperature

- 0 to 50C (Operating)

- Voltage

- 24V DC

- Language Support

- Multiple (based on configuration)

- Operating System

- Siemens Firmware

- Programming Tool

- ProTool

- Number of Function Keys

- 8

- Dimensions

- 195 x 98 x 47 mm

- Data Storage

- EEPROM 64 KB

- Power Consumption

- Max. 4 W

- Display Resolution

- 240 x 64 pixels

- Number of System Keys

- 4

- Backlight

- LED

SIMATIC OP7 HMI Display Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 1 Hours

About SIMATIC OP7 HMI Display

Versatile Industrial Control Panel

The SIMATIC OP7 stands out as a compact yet powerful HMI solution designed specifically for industrial applications. Its sturdy build, combined with advanced features like programmable keys, an integrated microprocessor, and multi-protocol connectivity, ensure seamless monitoring and control processes in factories and automation setups. With user-friendly configuration via ProTool, the OP7 delivers flexibility and efficiency in managing machine operations.

Reliable Performance and Durability

With an IP65-rated front panel, the OP7 is designed to withstand harsh industrial environments and resist dust and water. Its plastic and metal casing adds to its strength, while the LED-backlit display ensures readability under various lighting conditions. Operating reliably across temperatures from 0 to 50C, the panel is both dependable and energy efficient, making it suitable for continuous duty in critical automation applications.

FAQ's of SIMATIC OP7 HMI Display:

Q: How do I program the SIMATIC OP7 HMI Display?

A: You can program the SIMATIC OP7 using Siemens' ProTool software. This tool allows you to configure screen layouts, assign functions to keys, set up message and alarm displays, and customize language options. Once programming is complete, the configuration can be downloaded to the panel through supported communication ports.Q: What are the main benefits of using the SIMATIC OP7 in industrial machine control?

A: The OP7 offers several benefits, including compact panel-mount design, easy operation through function and system keys, robust IP65-rated front protection, and clear visual feedback with its LED-backlit, monochrome display. It enhances user interaction, increases operational safety with password protection, and provides reliable message and alarm monitoring.Q: When should I consider deploying the SIMATIC OP7 for my automation setup?

A: The OP7 is best suited for situations that require rugged operator interfaces for machinery. It's ideal when you need efficient, panel-mount monitoring and control, multi-language support, password security, and compatibility with automation protocols like RS-232, RS-485, and MPI.Q: Where can the SIMATIC OP7 be mounted within industrial environments?

A: This panel is designed for panel-mount installations within industrial control cabinets or operator stations. Thanks to its IP65-rated front, it can be positioned in locations exposed to dust, moisture, or mechanical impacts while safeguarding user inputs and display integrity.Q: What is the process to connect the OP7 HMI to automation devices?

A: The OP7 supports standard industrial connectivity through RS-232, RS-485, and MPI interfaces. You will typically connect the panel to programmable logic controllers (PLCs) or other automation devices using suitable cables-up to approximately 15 meters in length, depending on your installation.Q: How does the OP7 manage data and ensure secure access?

A: The OP7 uses a 64 KB EEPROM for data storage, safeguarding configurations and logs even during power loss. It supports password protection, ensuring that only authorized personnel can access critical settings or sensitive machine controls, thereby maintaining operational security.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PLC Automation Products Category

SIMATIC S7-1200 CPU 1211C PLC

Price 6500 INR / Piece

Minimum Order Quantity : 1 Piece

Processor Type : NA

Automation Grade : NA

Cable Length : NA Millimeter (mm)

Screen Size : NA Millimeter (mm)

LT LX-PWR220

Price 17000 INR / Piece

Minimum Order Quantity : 1 Piece

Processor Type : Microcontroller Based

Automation Grade : Automatic

Cable Length : 1.5 Meter

Screen Size : 2.8 Inch LCD

Telemecanique Modicon M340 PLC

Price 13500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Processor Type : ARM 32bit RISC

Automation Grade : Automatic

Cable Length : Depends on module; typically up to 100m for Ethernet

Screen Size : No Integrated Display

PLC Automation Control Panel

Price 12500 INR / Piece

Minimum Order Quantity : 1 Piece

Processor Type : HighSpeed Microprocessor

Automation Grade : Automatic

Cable Length : Standard: 2 Meter extension provided

Screen Size : 7 Inch Touch Screen HMI

GST : 24BUSPP5705J1Z5

|

|

SANJAR AUTOMATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry